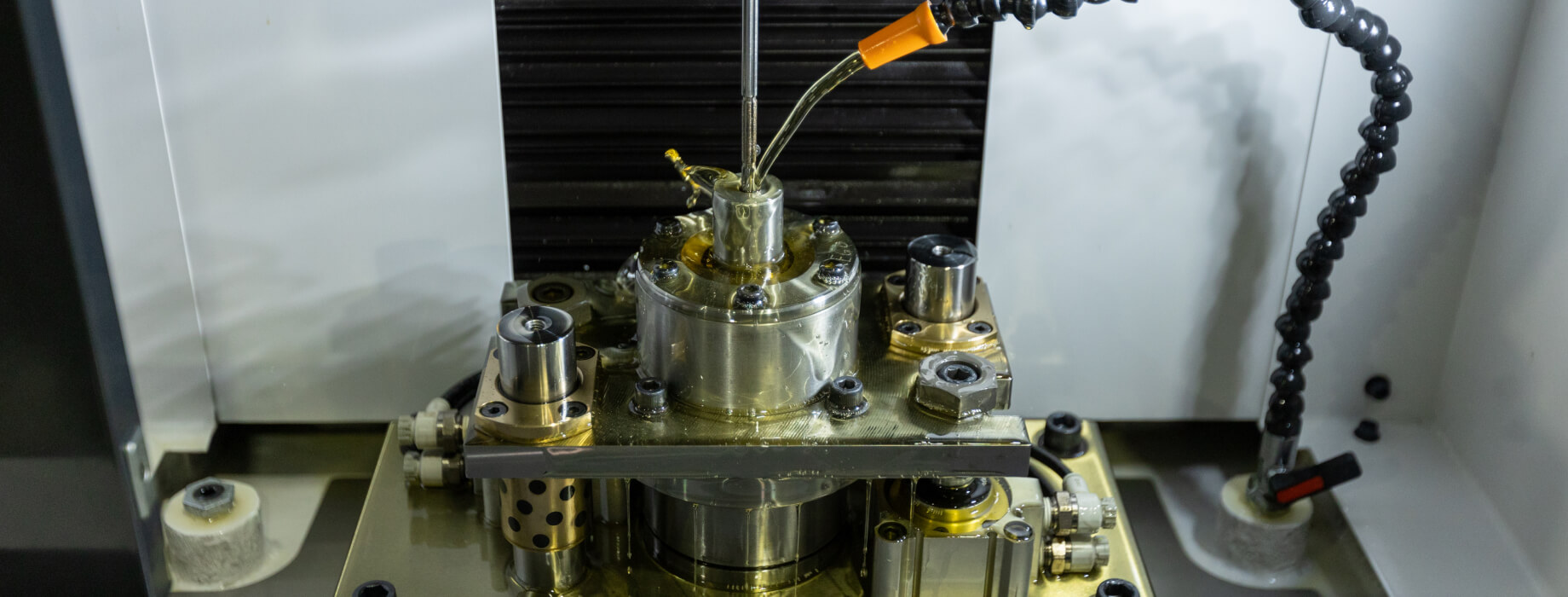

長岡から世界を創る

長岡Qualityで世界を創る。

'研鑽を積む、こつこつと。

真面目に取り組む、粛々と。

私たちは職人たちの「ものづくり」に対する

愛情と熱量で、

世界の「ものづくり」に貢献します。'

-

-

長岡Qualityで世界を創る工作機械メーカー

DMG MORI Precision Boring株式会社の想いや歴史についてご紹介します。

展示会出展情報

| 日時 | 展示会名 | 会場 | 出展内容 |

|---|---|---|---|

| 2024年03月08日(金) ~ 03月09日(土) |

DMG-PB スマイルフェア45 |

五誠機械産業株式会社 | KBM-11S(パネル展示) 加工見積システム(パネル展示) |

| 2024年05月16日(木) ~ 05月18日(土) |

工作機械 2024 大阪どてらい市 |

インテックス大阪 | パネル展示 加工ビデオ放映 |